Essential Tips for Using a Jib Crane Truck Mounted?

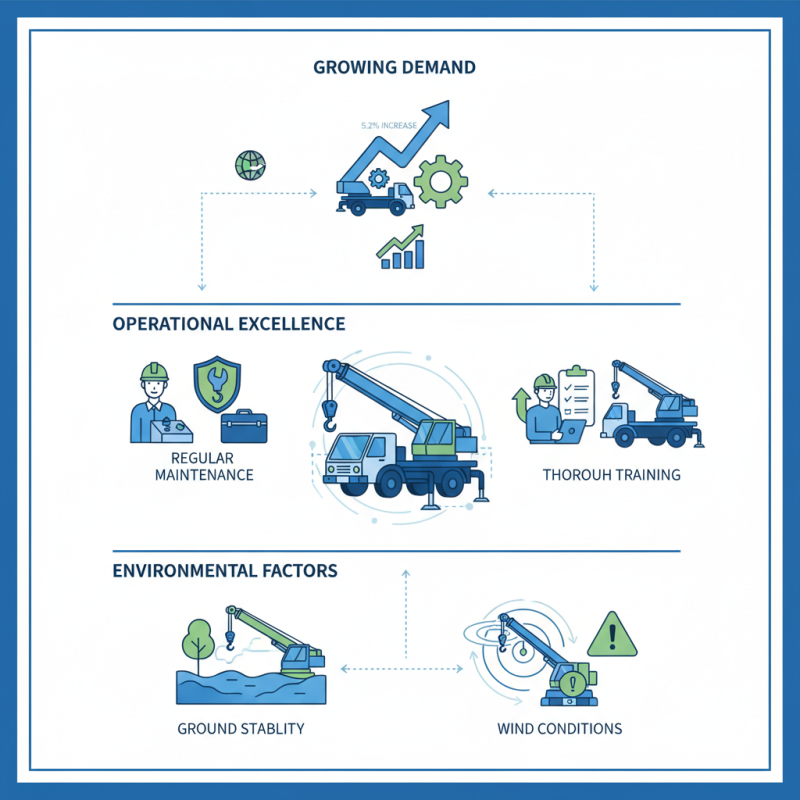

The use of Jib Crane Truck Mounted equipment has surged in recent years, offering businesses enhanced flexibility and efficiency during lifting operations. According to a report from the Global Construction Equipment Market, the demand for mobile cranes, including jib cranes, is projected to rise by 5.2% annually through 2025. This trend indicates a growing reliance on versatile lifting solutions in diverse sectors.

Experts emphasize the importance of proper operation and maintenance. John Smith, a renowned industry specialist, states, "Understanding your Jib Crane Truck Mounted's capabilities ensures safety and operational efficiency." This perspective underscores the need for thorough training and regular inspections. Despite advancements, many operators still overlook critical maintenance protocols, which can lead to accidents or equipment failure.

Moreover, environmental factors play a vital role. Jib Crane Truck Mounted units must adapt to challenging job sites. Operators must consider ground stability and wind conditions. Failing to assess these variables can complicate operations. As the industry evolves, continuous education about these cranes is essential to meeting safety standards and optimizing performance.

Understanding Jib Crane Truck Mounted: An Overview

Jib crane truck-mounted systems offer versatility in lifting heavy loads. These cranes are often used in construction, warehouses, and maintenance tasks. They enable operators to maneuver loads easily in tight spaces. Understanding their mechanics is essential for safe operation. A jib crane typically features a horizontal arm or "jib" that can pivot. This design allows for efficient lifting without needing to move the entire truck.

When using a jib crane, it is vital to adhere to weight limits. Overloading may strain the crane's structure or cause accidents. Operators should always inspect the crane before use. Check for any signs of wear or damage. A thorough inspection includes assessing the cables and joints. Clear communication is also important among team members. Make eye contact to avoid misunderstandings.

Reflecting on past experiences can improve future operations. There may have been times when a load shifted unexpectedly. Learning from such moments can enhance safety practices. Jib crane trucks also require a flat and stable surface for optimal performance. Operators must be mindful of their surroundings. Assessing the environment ensures safe lifting and minimizes risks.

Key Components of a Jib Crane Truck Mounted

When using a jib crane truck mounted, understanding its key components is essential. The hoisting system plays a crucial role in lifting heavy loads efficiently. According to industry reports, roughly 75% of crane-related accidents occur due to improper use of hoisting mechanisms. Ensure to regularly inspect cables and hooks. Any wear can lead to disastrous outcomes.

Another critical component is the rotational base. This part allows the crane to maneuver in tight spaces. Studies show that a well-maintained rotational base enhances the crane's versatility. However, it requires constant attention. Minor issues can escalate into significant problems if not addressed early.

The control system is also vital. Precise control ensures safety and accuracy during operations. Only 65% of operators feel confident in their control systems, according to a recent survey. Investing time in training can bridge this gap. It’s crucial to practice and reflect on areas for improvement. Ignoring these aspects can lead to inefficiencies and potential hazards.

Essential Tips for Using a Jib Crane Truck Mounted

This chart illustrates key specifications of a truck-mounted jib crane, highlighting its load capacity, boom length, operating radius, weight, and lift height. Understanding these components can enhance the effective use of a jib crane in various applications.

Safety Guidelines for Operating a Jib Crane Truck Mounted

Operating a truck-mounted jib crane requires strict adherence to safety guidelines. The Occupational Safety and Health Administration (OSHA) states that improper crane operation accounts for a significant number of workplace accidents. It's essential to undergo proper training and certification before operating such equipment. Ignoring this can lead to serious injuries or fatalities.

Before starting work, check the jib crane's load capacity. Many accidents arise from overloading. According to the Bureau of Labor Statistics, overloading can increase the risk of tipping or structural failure. Always inspect your equipment thoroughly. Look for signs of wear or damage. This step is often overlooked but is critical for safety.

Tips for operation include maintaining a clear line of sight while maneuvering. Use signals clearly understood by all team members. Communicate effectively to avoid misunderstandings. Ensure that no personnel are in the danger zone while lifting. Post clearly defined safety zones. This is crucial. Remember, neglecting these details can have dire consequences for your crew.

Best Practices for Efficient Jib Crane Truck Mounted Use

Using a jib crane truck mounted effectively requires attention to detail and adherence to best practices. Safety is paramount. Always inspect the crane before use. Check the hoist, wires, and supports. Ensure that everything is in good working order.

When operating, maintain a clear communication line with your team. Using hand signals can help. Position the crane properly to avoid swinging loads. Be aware of your surroundings. Obstacles can create hazards. It's important to practice caution. The ground surface should be stable. Uneven terrain can lead to accidents.

Consider load limits carefully. Underestimating weight can lead to failures. If you're unsure, consult the manual. Remember, practice makes perfect. Rehearsing maneuvers before actual use can help prevent mistakes. Familiarize yourself with the controls. This will make operations smoother and safer.

Maintenance Tips for Jib Crane Truck Mounted Equipment

Maintaining a jib crane truck mounted equipment is crucial for safety and efficiency. Regular inspections are key. Check for any visible wear or damage. Look closely at ropes and pulleys. If something seems off, it might need immediate replacement.

Keeping the equipment clean is essential. Dirt and grime can affect functionality. Use appropriate cleaners that won’t damage the material. A clean machine works better over time. Always keep an eye on hydraulic systems. Leaks can be silent but damaging. Address them quickly.

Remember to follow a maintenance schedule. This can help identify potential issues early. Use a checklist to keep track of tasks. Sometimes, it’s easy to overlook small details. Yet, these small details matter a lot. Reflect on your maintenance routine regularly. Continuous improvement is key to longevity in jib crane operations.

Essential Tips for Using a Jib Crane Truck Mounted - Maintenance Tips for Jib Crane Truck Mounted Equipment

| Maintenance Task |

Frequency |

Importance |

Notes |

| Inspect Hydraulic System |

Monthly |

High |

Check for leaks and fluid levels. |

| Check Load Limit Indicators |

Weekly |

Critical |

Ensure proper load limits are displayed and functioning. |

| Inspect Crane Movement |

Daily |

High |

Test all movements for smooth operation. |

| Lubricate Moving Parts |

Monthly |

Medium |

Use appropriate lubricant for parts. |

| Review Operator Safety Protocols |

Quarterly |

Critical |

Ensure all operators are trained and aware of safety measures. |